歡迎訪問濟南科爾超聲波設(shè)備有限公司網站!

91污_91污视频_91免费视频污_91视频污下载

91污_91污视频_91免费视频污_91视频污下载

常見問題(tí)

五金超聲波清洗機和超聲波清洗機(jī)的區別在哪(nǎ)?

作者:admin來源:http://www.ahfanglei.com/時間:2023-10-06

很多工業產品生產廠商可能都會使用(yòng)過超聲波清(qīng)洗,在很多行業都可(kě)以用到這個設備,它的清洗目的對工件表麵進行清(qīng)洗,使工件表(biǎo)麵的汙垢脫離,從而達到一(yī)個(gè)潔淨的效果。那麽這樣(yàng)說來,很多人就明白了超(chāo)聲波清洗實際就是清洗一些表麵的可見的物質。

Many industrial product manufacturers may have used ultrasonic cleaning, which can be used in many industries. Its cleaning purpose is to clean the surface of the workpiece, remove dirt from the surface, and achieve a clean effect. So in this way, many people understand that ultrasonic cleaning is actually cleaning some visible substances on the surface.

先分析一下等離子清洗機(jī)的由來,等離子清洗機,又名等離子設(shè)備,目前在國內可以生產(chǎn),研發(fā),的廠家並不是很多(duō),很多廠商在大部分的(de)都是接觸(chù)到的一些貿易商,而非真正的(de)等離子設備生產廠家(jiā)。

First, let's analyze the origin of plasma cleaning machines. Plasma cleaning machines, also known as plasma equipment, are currently not many manufacturers that can produce, research and develop them in China. Many manufacturers are mostly in contact with some traders, rather than real plasma equipment manufacturers.

接下來91污說等離子清洗機的清洗目的,等離(lí)子清洗機是利用等離子體達(dá)到常規清洗所不(bú)能達到的效果,比如說等離(lí)子體的活性組分是離子,電子和光(guāng)子等組成,那麽它所達到的清洗效果(guǒ)肯定和一般(bān)的超聲波(bō)清洗機之類的清洗產品是不一樣的。等(děng)離子清洗機利用這些離子和光子等活性組分來處理工件的表麵,而(ér)達到清洗的目的,很顯然這樣的清洗效果(guǒ)要比普通(tōng)的清洗來得更加的好。

Next, we will talk about the cleaning purpose of plasma cleaning machines. Plasma cleaning machines use plasma to achieve effects that conventional cleaning cannot achieve. For example, if the active components of plasma are ions, electrons, and photons, the cleaning effect it achieves will definitely be different from that of ordinary ultrasonic cleaning products. The plasma cleaning machine uses active components such as ions and photons to treat the surface of the workpiece, achieving the purpose of cleaning. Obviously, this cleaning effect is better than ordinary cleaning.

那麽91污來說(shuō),五金超聲波清洗機可不可以取(qǔ)代超聲波清洗機呢?答案肯定是否定的,因為超聲波清洗機是清潔(jié)表麵可見的物質的一(yī)個設備,而等離子清洗機則不是(shì)這樣的(de)。等離子清洗機是清洗表麵的有機物,使產品改性,提(tí)升不良率,做表麵活化等效果(guǒ)的。

So, can hardware ultrasonic cleaning machines replace ultrasonic cleaning machines? The answer is definitely no, because ultrasonic cleaning machines are devices that clean visible substances on the surface, while plasma cleaning machines are not. Plasma cleaning machine is used to clean organic substances on the surface, modify products, increase defect rates, and achieve surface activation effects.

所(suǒ)以是不能取代(dài)超聲波清洗機的。那麽91污說它們是一個(gè)相輔相成的一(yī)個東西,做完超聲波清洗之後來做等離子清洗機(jī)清洗的話將會使產(chǎn)品的性能達到更好的效(xiào)果。相信很多工業產品生產廠商在結合使用這兩類(lèi)產品的時候會有相同的感覺和認(rèn)同。

So it cannot replace ultrasonic cleaning machines. So we say they are complementary things. After ultrasonic cleaning, using a plasma cleaning machine for cleaning will improve the performance of the product. I believe many industrial product manufacturers will have the same feeling and recognition when using these two types of products together.

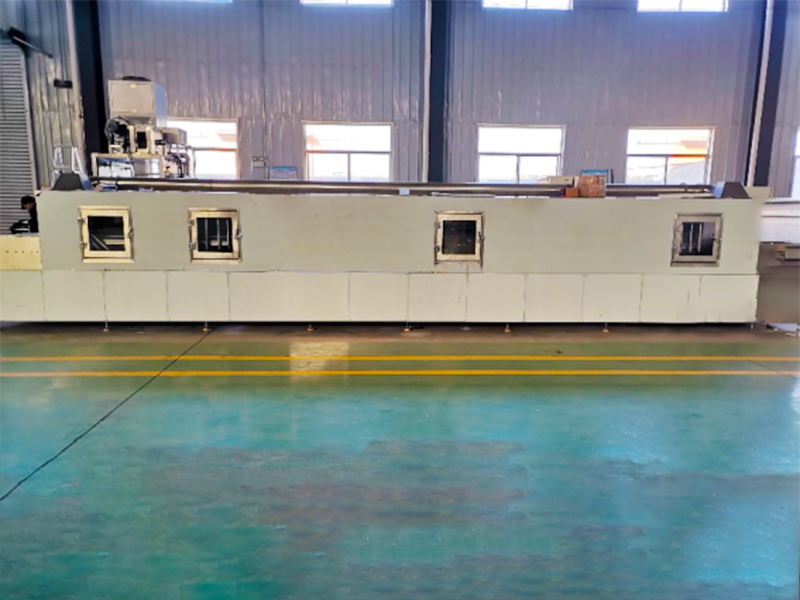

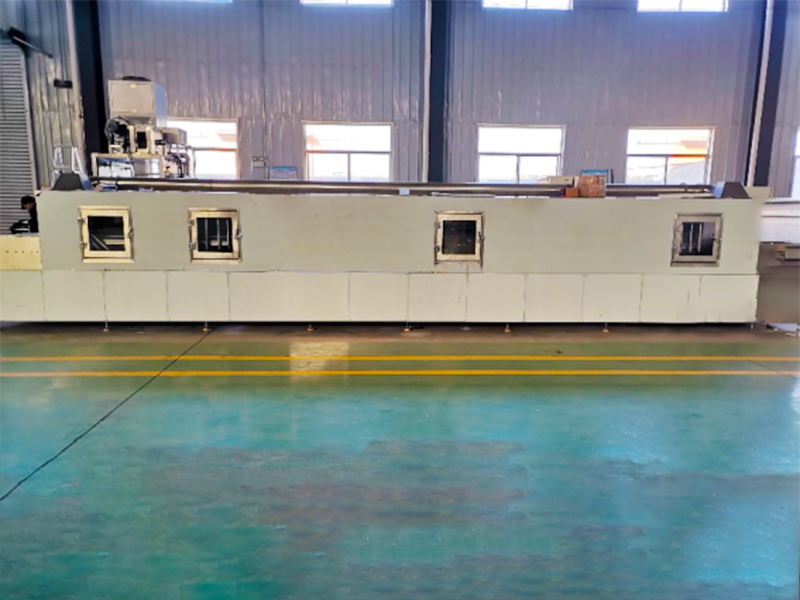

五金超聲波(bō)清洗機是一種(zhǒng)幹法清洗,主要清洗(xǐ)很微小的氧化物和汙染物.它是用工作氣體在電磁場的作用下激發出等離子體與物體表麵產生物理和化學反應,從而達到清洗的目的(de);而超聲波(bō)清洗機是一種濕法(fǎ)清洗,主要是清洗很明顯的灰塵和汙染物,屬於一種粗略的清洗(xǐ).它是(shì)用液體(水或(huò)者溶劑)在超聲波的震動作用下對物體(tǐ)進行清(qīng)洗,從而達到清洗的目的.華澤機械生產的等離子清(qīng)洗機就是一種清洗很精(jīng)細、很徹底的表麵處理設備

Hardware ultrasonic cleaning machine is a dry cleaning method that mainly cleans very small oxides and pollutants. It uses working gas to excite plasma under the action of electromagnetic fields to generate physical and chemical reactions with the surface of objects, thereby achieving the purpose of cleaning; The ultrasonic cleaning machine is a type of wet cleaning, mainly used to clean obvious dust and pollutants, belonging to a rough cleaning. It uses a liquid (water or solvent) to clean objects under the vibration of ultrasound, thereby achieving the purpose of cleaning. The plasma cleaning machine produced by Huaze Machinery is a very precise and thorough surface treatment equipment for cleaning

本文(wén)的精(jīng)彩內容由超聲波清洗機提供知識提供,本網(wǎng)站還有很多的(de)精彩內容,更多(duō)的內容您可以點擊進入:http://www.ahfanglei.com91污有專門的(de)客服為您解答(dá)問題(tí)

The exciting content of this article is provided by the knowledge provided by ultrasonic cleaning machines. There are also many exciting content on this website, and you can click to enter more content: http://www.ahfanglei.com We have dedicated customer service to answer your questions

推薦產品

推薦文章(zhāng)

公司(sī):濟南科爾超聲波設備有限公司

公司(sī):濟南科爾超聲波設備有限公司  熱線:18663767799

熱線:18663767799 地址:山東省濟南市濟陽區創業路(lù)與啟航街交叉口南40米(mǐ)

地址:山東省濟南市濟陽區創業路(lù)與啟航街交叉口南40米(mǐ)

常見問題

常見問題

聯係91污

聯係91污

谘詢電話:18663767799

谘詢電話:18663767799 E-MAIL:jnkergs@163.com

E-MAIL:jnkergs@163.com 地址:山(shān)東省濟南市濟(jì)陽區創業(yè)路與啟航街交(jiāo)叉口南40米

地址:山(shān)東省濟南市濟(jì)陽區創業(yè)路與啟航街交(jiāo)叉口南40米 魯公網安備 37011202001385號

魯公網安備 37011202001385號